Global Manufacturing Management in the Cloud

NetSuite is engineered to streamline mission-critical processes. In turn, this allows businesses to continue focusing on what they do best and to react to new market opportunities swiftly and confidently. From financials to supply chain management to billing and beyond, NetSuite ERP gives companies clear visibility and control of their business.

Features

Product Data Management

Everything you need to define, manage and maintain your products throughout their

lifecycle.

Work Order Management

Simple, effective and efficient production management for both discrete and batch-driven manufacturers.

Planning and Scheduling

Easily coordinate the materials you need for production and schedule your operations to ensure on-time delivery

Quality

Assurance

Make sure your product is produced and delivered the way you intended with automated quality control.

Manufacturing Execution System

Get real-time updates from production via barcode scanning and our interactive hmi /

tablet device

Benefits

Effectively Manage Global Manufacturing Operations

Manage your entire manufacturing operation regardless of location.

Location

Irrelevance

Manufacture the same item in different ways at each location depending on capabilities.

Increase On-

Time Delivery

Accurately cost, track and schedule production with our finite capacity real-time engine.

Reduce Cost

of Quality

Reduce your cost of goods sold by optimizing cost of quality with embedded quality management.

Envision Your Manufacturing Operations in the Cloud

Get In Touch

We're happy to help you in anyway we can.

Drop us a line and we'll get back to you as soon as possible!

Features

Product Data Management

Accelerate product development

The research, development and design of new products or the re-design of existing ones is the lifeblood of any manufacturing company, but in many cases the design and engineering departments are completely disconnected from the ERP system. What that means is engineers spend a lot of their time answering queries from other areas of the company regarding product status, revision levels, design progress, etc. NetSuite offers a host of native collaboration features that makes this information available on a self-service basis across the organization.

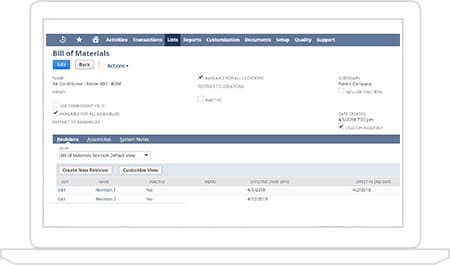

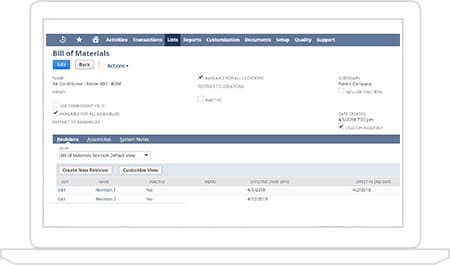

Assembly Items

The Bill Of Materials is established and maintained in NetSuite through the use of assembly items. Using this approach ensures consistency for the user as they create and edit all of the information that is required to effectively manage multi-level BOM structures with minimal effort. Advanced options are available such as the ability to mark items as phantoms, define the expected yield, maintain revisions and/or set effectivity and expiration dates to ensure you always build the right version of your product.

The Bill Of Materials is established and maintained in NetSuite through the use of assembly items. Using this approach ensures consistency for the user as they create and edit all of the information that is required to effectively manage multi-level BOM structures with minimal effort. Advanced options are available such as the ability to mark items as phantoms, define the expected yield, maintain revisions and/or set effectivity and expiration dates to ensure you always build the right version of your product.

Key Capabilities:

- Multi-Level BOMs

- Phantoms

- Revision Control

Advanced Bill of Materials

For those companies who want more control over their product data structure, the optional Advanced BOM functionality introduces many additional features. Once enabled, users can create multiple BOM’s for each item—so for example, you can create and maintain separate engineering and production BOMs. Additionally, each BOM can be location-specific or can be linked to multiple end SKUs—ideal where you perhaps sell the same item under multiple brands.

For those companies who want more control over their product data structure, the optional Advanced BOM functionality introduces many additional features. Once enabled, users can create multiple BOM’s for each item—so for example, you can create and maintain separate engineering and production BOMs. Additionally, each BOM can be location-specific or can be linked to multiple end SKUs—ideal where you perhaps sell the same item under multiple brands.

Key Capabilities

- Customizable record structures for complete design control

- Location-specific BOMs

- Link the BOM to multiple end SKUs

- Enhanced Revision control

- Easier integration with PLM systems

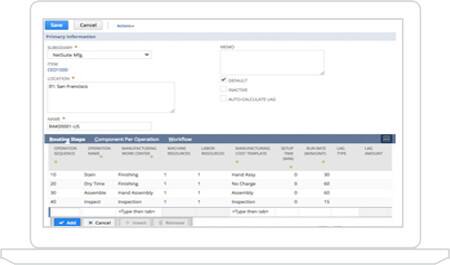

Routings

NetSuite’s routing functionality enables you to easily define the people, machines, work centers and time it takes to make your product. This information when combined with our cost templates determines the expected labor, machine and indirect cost to enable you to track the appropriate level of cost detail from your manufacturing process. When using our Advanced Manufacturing feature, you will also be able to automatically generate a finite capacity schedule by defining additional characteristics unique to your facility. Additionally, our routing functionality can be defined to be location specific where necessary.

- Finite or Infinite Capacity Scheduling

- Location-specific Routings

- Flexible Cost Templates

Item Management

NetSuite has a unique approach to item definition where all items start off from the same screen and then the user picks the type of item they want to create. This allows us to present an item definition screen that has been tailored to that specific item type that shows and requires only the information that is necessary. Using our SuiteFlow functionality, we can easily set up automated item numbering, hide or require additional fields, and automate an approval process.

NetSuite has a unique approach to item definition where all items start off from the same screen and then the user picks the type of item they want to create. This allows us to present an item definition screen that has been tailored to that specific item type that shows and requires only the information that is necessary. Using our SuiteFlow functionality, we can easily set up automated item numbering, hide or require additional fields, and automate an approval process.

- Quick and Easy Setup

- Mandatory and Custom Fields

- Easy Mass Updating

Document Management

NetSuite’s File Cabinet was specifically designed as the central repository for all documents, files and attachments that you need to run your business. Files can be manually uploaded through the system and attached to virtually any record in NetSuite including Customers, Vendors, Orders, etc. By using the optional file drag n drop suitelet, you add the ability to automatically upload and update files by fragging them from your desktop. Files are stored in folders with unique security permissions.

NetSuite’s File Cabinet was specifically designed as the central repository for all documents, files and attachments that you need to run your business. Files can be manually uploaded through the system and attached to virtually any record in NetSuite including Customers, Vendors, Orders, etc. By using the optional file drag n drop suitelet, you add the ability to automatically upload and update files by fragging them from your desktop. Files are stored in folders with unique security permissions.

- Securely Stored and Managed

- Captures email attachments

- Cross-reference with NetSuite records

Engineering Change Orders

The Engineering Change Order allows users to capture requested changes, document and share them with all interested parties for approval and then automatically implement them once approved. Change orders can be categorized by type and can update process and documentation changes in addition to material product changes. When used in conjunction with the Quality and Case management features, NetSuite provides complete control over the lifecycle of your products—ensuring that you always plan, manufacture and deliver the current and correct designs.

The Engineering Change Order allows users to capture requested changes, document and share them with all interested parties for approval and then automatically implement them once approved. Change orders can be categorized by type and can update process and documentation changes in addition to material product changes. When used in conjunction with the Quality and Case management features, NetSuite provides complete control over the lifecycle of your products—ensuring that you always plan, manufacture and deliver the current and correct designs.

- Centrally manage all change requests

- Flow proposed changes through SuiteApprovals

- Automatically implement and update all related BOMs after approval

Work Order Management

Easily create, release, close and complete work orders with automatic scheduling for efficient and scalable production control

NetSuite’s manufacturing functionality can be configured depending on how much control and influence you want over your production process. In addition to using the work order as the control document, NetSuite also offers the ability to work in an environment without work orders for manufacturers are following lean principals. NetSuite’s advanced manufacturing module offers the ability to manufacture in batches with automatic batch creation, full traceability, production control and scheduling.

Discrete Manufacturing

NetSuite offers discrete manufacturers many options for how they manage their production processes regardless of their size, complexity or business maturity. Whether you want to work in an environment without work orders, backflush all of the materials upon completion, issue and track materials and labor as work in process cost or define and track labor through a routing, NetSuite has the features to get you the information you need.

NetSuite offers discrete manufacturers many options for how they manage their production processes regardless of their size, complexity or business maturity. Whether you want to work in an environment without work orders, backflush all of the materials upon completion, issue and track materials and labor as work in process cost or define and track labor through a routing, NetSuite has the features to get you the information you need.

Key Capabilities:

- Work Orders & Assemblies

- WIP & Routings

- Advanced Manufacturing

Batch Processing

NetSuite Advanced Manufacturing offers companies the flexibility to define batch sizes during the production process and automatically creates batch records. Every batch is processed and tracked uniquely and when combined with NetSuite’s native lot tracking functionality provides complete end-to-end traceability. Machines, employees, work centers and assets are then scheduled and assigned to each individual batch and the manufacturing execution systems barcode and tablet interfaces ensure that all this information is tracked and updated in real time.

NetSuite Advanced Manufacturing offers companies the flexibility to define batch sizes during the production process and automatically creates batch records. Every batch is processed and tracked uniquely and when combined with NetSuite’s native lot tracking functionality provides complete end-to-end traceability. Machines, employees, work centers and assets are then scheduled and assigned to each individual batch and the manufacturing execution systems barcode and tablet interfaces ensure that all this information is tracked and updated in real time.

- Automated Batch Management

- Full Traceability

- Quality Control

Shop Floor Control

Obtaining accurate information from the shop floor is vital to all aspects of running a manufacturing business and without it you run the risk making critical business decisions without all of the necessary information. Barcode scanners have typically been used to gather production information, but they are limited in the amount of information they can feed back to the user / operator. So NetSuite offers an intelligent tablet interface that provides instant feedback and visual warnings to the user when there are things they need to attend to.

Obtaining accurate information from the shop floor is vital to all aspects of running a manufacturing business and without it you run the risk making critical business decisions without all of the necessary information. Barcode scanners have typically been used to gather production information, but they are limited in the amount of information they can feed back to the user / operator. So NetSuite offers an intelligent tablet interface that provides instant feedback and visual warnings to the user when there are things they need to attend to.

- Tablet Interface

- Real-time updates

- Shop Floor to Top Floor Reporting

Planning and Scheduling

NetSuite provides the tools to easily plan your material supplies and schedule production for on-time delivery

Planning and Scheduling are often used together but understanding the relationship between them and how they interact is critical to the success of your business. NetSuite delivers the functionality you need to effectively plan your material purchases, position your inventory and schedule your employees, machines and work centers in production to make on-time delivery an achievable priority. NetSuite’s broad and tightly integrated business platform will help ensure that you achieve all of this through optimized business practices to ensure maximum profitability and customer satisfaction levels.

Forecasting

NetSuite’s Demand Planning module offers several ways to calculate and predict demand based on historical demand, open opportunities and manually entered or imported sales forecasts. Whether you want the system to review monthly or weekly demand and generate forecasts using moving average, linear regression or seasonal average calculations you will have the ability to review and edit the forecasted demand before proceeding to supply planning. You can also have the system create demand based on sales forecasts.

NetSuite’s Demand Planning module offers several ways to calculate and predict demand based on historical demand, open opportunities and manually entered or imported sales forecasts. Whether you want the system to review monthly or weekly demand and generate forecasts using moving average, linear regression or seasonal average calculations you will have the ability to review and edit the forecasted demand before proceeding to supply planning. You can also have the system create demand based on sales forecasts.Key Capabilities:

- Analyze Historical Demand

- Use Sales Forecasts

- Import from CSV, Web Services

Capacity Planning

Production scheduling is one of the most critical elements of running a manufacturing facility, but is also one that is commonly done outside of a system because of the complexities involved with doing it accurately and with precision. The advanced scheduling engine can ensure availability of the most appropriate resource while generating a unique scheduling code that allows for advanced techniques such as light to dark sequencing.

Production scheduling is one of the most critical elements of running a manufacturing facility, but is also one that is commonly done outside of a system because of the complexities involved with doing it accurately and with precision. The advanced scheduling engine can ensure availability of the most appropriate resource while generating a unique scheduling code that allows for advanced techniques such as light to dark sequencing.

- Multiple Constraints

- Scheduling Codes for sequencing

- Real-time updates from MES

Material Requirements Planning

MRP is one of the standard methods for balancing demand and supply. NetSuite’s Demand Planning functionality provides the ability to explode BOM’s, check inventory and safety stock levels, review demand and analyze supply before generating planned orders. And it’s all done in the cloud with minimal overhead.

MRP is one of the standard methods for balancing demand and supply. NetSuite’s Demand Planning functionality provides the ability to explode BOM’s, check inventory and safety stock levels, review demand and analyze supply before generating planned orders. And it’s all done in the cloud with minimal overhead.

- Utilize the power of the cloud

- Generate planned orders

- Multi-location planning

Quality Assurance

Set up inspection plans, track test results and evaluate vendors to ensure optimal quality

Designing and manufacturing a product of high quality doesn’t happen by accident, it requires a company-wide commitment. NetSuite’s Quality Management solution has been designed to help you deliver the highest quality in your products with minimal overhead. Quickly and easily define the tests you want to perform, set parameters to evaluate the results, apply those to the relevant items and operations for receiving and in-process testing. NetSuite will automatically tell you what to test, collect the results use workflows for dispositioning.

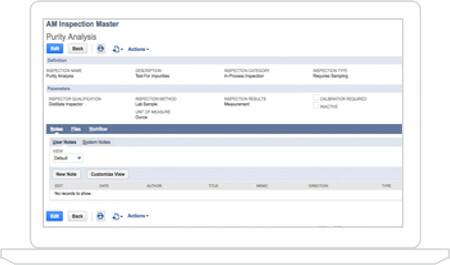

Test Definition

NetSuite uses a master list of inspection profiles that are defined in advance that specify the type of inspection / test that is to be performed, acceptable limits, the minimum qualifications of the inspector and type / category / method of inspection. Additionally, we can denote whether calibration is required where the test involves equipment.

NetSuite uses a master list of inspection profiles that are defined in advance that specify the type of inspection / test that is to be performed, acceptable limits, the minimum qualifications of the inspector and type / category / method of inspection. Additionally, we can denote whether calibration is required where the test involves equipment.Key Benefits:

- Centrally managed list of tests / inspections

- Enforce minimum Inspector qualifications

- Capture measurements and compare to pass / fail limits

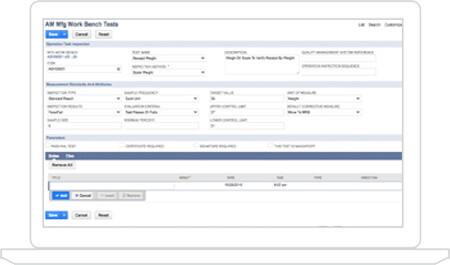

Receiving & In-process Inspections

Tests that are to be performed on an item can be performed on demand, upon receipt and during the process of manufacturing. As the tests have already been defined, they are easily attached to the item or operation to ensure compliance with your company’s quality control procedures. Items that fail the inspection can be moved to a hold location for further processing.

Tests that are to be performed on an item can be performed on demand, upon receipt and during the process of manufacturing. As the tests have already been defined, they are easily attached to the item or operation to ensure compliance with your company’s quality control procedures. Items that fail the inspection can be moved to a hold location for further processing.

- Enforce compliance to minimum quality standards

- Automatic prompting for inspection / test results

- Workflow based handling of non-conforming materials

Data Collection

Establishing the test / inspection criteria and when they are to be performed are critical steps, but providing a user friendly way to capture the results is vital. In many cases this takes place whether in the receiving area or on the shop floor and so NetSuite’s tablet interface provides a convenient way to capture and process test results regardless of the environment or location.

Establishing the test / inspection criteria and when they are to be performed are critical steps, but providing a user friendly way to capture the results is vital. In many cases this takes place whether in the receiving area or on the shop floor and so NetSuite’s tablet interface provides a convenient way to capture and process test results regardless of the environment or location.

- User friendly, interactive application

- Device agnostic—runs on any browser based tablet

- Real-time processing of inspection results

Manufacturing Execution System

NetSuite provides innovative, real-time, cloud-based solutions to get the most up-to-date information from production

Obtaining information from your production facilities, regardless of location, is vital to the short term execution of your business and your long term strategic planning. NetSuite offers both a traditional barcode scanner-based interface and an innovative and interactive tablet app. While the barcode scanner is designed for speed of data entry, the tablet device features a rich interface that provides unparalleled feedback about what’s happening in the user’s work center and / or machine.

Barcoding

NetSuite’s Advanced Manufacturing has a native barcoding application that will run on any device with a browser and streamline the collection of the most common transactions including labor tracking, work order completions, material movements, PO receipts and shipping. All native shop floor facing reports can be printed with barcodes to ensure data accuracy.

NetSuite’s Advanced Manufacturing has a native barcoding application that will run on any device with a browser and streamline the collection of the most common transactions including labor tracking, work order completions, material movements, PO receipts and shipping. All native shop floor facing reports can be printed with barcodes to ensure data accuracy.

Key Capabilities:

- Standard interface

- Barcoded Travelers and Dispatch Lists

- Improved Data Accuracy

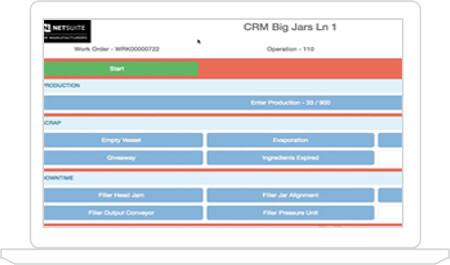

HMI / Tablet

Obtaining accurate information from the shop floor is vital to all aspects of a manufacturing business and without it, you run the risk making critical business decisions without all of the necessary information. Barcode scanners have typically been used to gather production information, but they are limited in the amount of information they can feed back to the user / operator. So NetSuite offers an intelligent tablet interface that provides instant feedback and visual warnings to the user.

Obtaining accurate information from the shop floor is vital to all aspects of a manufacturing business and without it, you run the risk making critical business decisions without all of the necessary information. Barcode scanners have typically been used to gather production information, but they are limited in the amount of information they can feed back to the user / operator. So NetSuite offers an intelligent tablet interface that provides instant feedback and visual warnings to the user.

- User configurable interface

- Real-time or delayed processing

- Visual indicators of down time, etc.